Home | MEAT AND FOOD INDUSTRY | MEAT INDUSTRY | FERMENTED SAUSAGE

matured; can be stored without cutting and without chilling; muscle protein which has leaked to the surface of the meat particles has bonded the meat and fat tissue particles together during maturing; fatty tissue is visible in the case of coarse grains; in the case of air-dried and lightly smoked products, a whitish coating of micro-organisms may be visible on the intestine. In the case of firm raw sausages with coatings of micro-organisms, in white dipping mass or in casings with white pigment content, the absolute contents of meat protein free of connective tissue protein are one-tenth higher than those indicated for the individual varieties, and two-tenths higher for those with indications of a particularly high degree of ripeness (e.g. “permanently” “ripened” or “hard ripened”). The use of white dipping mass or white pigmented casing is indicated.

Basic materials are:

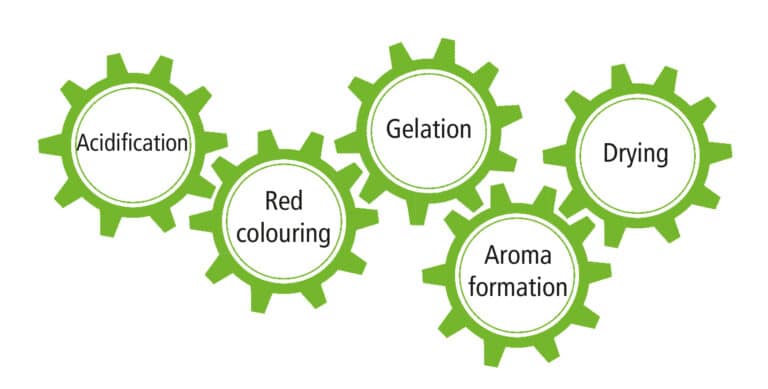

In Europe, the manufacture of fermented sausages has a long tradition, yet in the manufacture of sausages, many uncertainties keep on turning up especially when no special maturing facilities are available. The most important details and tricks are presented in this folder. For the ideal process of maturing, the following points must interplay perfectly:

Learn more about our wide selection of raw sausage seasonings and sturter cultures. Consult our raw sausage experts to find the right seasoning range for your production process.

In order to obtain microbiologically safe and always the same products, starter cultures should be used.

Contact us for any further information!

In the case of a raw sausage and a classic boiled sausage, with the exception of “white goods”, the consumer expects a red cured colour. Traditionally, this is formed by the curing process with the decomposition product nitrogen oxide from the nitrite curing salt. The antioxidant ascorbic acid and its derivatives are used to accelerate the curing process. These products are called reddening aids. At MOGUNTIA we know two classes of reddening aids.

Balanced spice mixtures for all aspects of traditional and modern raw sausage production with the perfect sugar combination. The spices are ideally matched to the MOGUNTIA starter cultures.

SALREIF®

The most traditional way of making raw sausage. By maturing with saltpetre, the unmistakable taste of long matured salami is achieved. The higher expenditure of time is compensated by a very special product.

BESSAVIT®

The classic way of making raw sausage. By using nitrite curing salt, you work effectively and quickly – and in a natural maturing process.

FIXREIF®

The fast way to make raw sausage and for all impatient people. The acidification does not only come from the micro-organisms but mainly from the GDL. Thus it works under almost all conditions.

FIXREIF® GdL free

The modern way of maturing raw sausages. Instead of the GdL, special starter cultures and a balanced sugar combination work here. This means that the process is just as fast and natural under the right climatic conditions as with GdL.

FF 110

For extra fast raw sausage maturation in combination with PrestoSTART® Aromatic starter cultures. Under natural maturing conditions, the specially contained sugar combination is metabolized by the lactic acid bacteria.

Emulsions, or more precisely pre-emulsions, are used to bring processing materials and foodstuffs into a production-ready state. In this way, vegetable fat and protein materials, as well as those in non-standard animal forms (e.g. flavoured and kidney fat) can be prepared in such a way that they are similar to the processability of a common bacon material. The same applies to animal and vegetable proteins.

SAFTEX®

stands for the group of functional saccharides. From monosaccharides (dextrose) to polisaccharides (fibres and dietary fibres). Depending on the application, these products can be used for pre-emulsions, as syneresis blockers, as structuring agents, for fibre enrichment or to increase the water-binding capacity.

FAT BINDER

This, on the other hand, provides the perfect basis for all types of pre-emulsions, especially meat, chicken skin and fat emulsions and for the production of fat and meat substitutes.

Flavour enhancers are the Feng Shui of meat processing. They create the harmony of taste without appearing dominant themselves.

Classic flavour enhancers from the GLUTESSA® series help meat products to achieve their meaty umami. They are classically based on monosodium glutamate and can contain additional flavour components depending on the type.

The products from the AROSTAR® series take a different approach here. In keeping with the times, they manage without the addition of flavour-enhancing additives. AROSTAR® products are the haute cuisine of tasting. As in classical cuisine, spices, seasonings and aromas have been combined in such a way that they perfectly flavour the meat product, and all this without monosodium glutamate.

Taste enhancer:

Dipping masses for raw sausage applications and raw ham have, apart from the visual enhancement

further advantages:

– Increase of the product variety

– By varying the surface finish, any number of end products can be obtained

– Upgrading of the product and optimisation of the grammage

– Customised solutions

– germ barrier, no loss of drying power during the course of the seasoning

As a modern family business and one of the leading spice manufacturers in Europe, we are not only responsible for food safety, but we also put quality first. With our new disinfection system based on infrared technology, we are able to treat products using short-wave infrared light in such a way that their microbiological contamination is significantly reduced. In contrast to other disinfection methods, there is no visual or sensory damage to the product.

The heat is brought directly into the core of the product by short-wave infrared radiation.

Due to the working principle of infrared light, the product to be treated is heated from the inside to the outside and is additionally exposed to heat from the outside. This results in a homogeneous distribution of heat.

The heat flow drives the moisture from the inside to the outside. After the moisture has left the product, it is discharged directly by the air circulation in the machine.

In addition to food safety, the quality of the raw materials is a priority. With the IRD technology we achieve :

Look no further, you have just found one! We are your expert manufacturer and supplier of flavoursome raw sausage seasoning! Our experts will be happy to advise you. You will also receive information on attractive prices and our wide product portfolio. Contact us!