Home | MEAT AND FOOD INDUSTRY | MEAT INDUSTRY | SCALDED SAUSAGE

Scalded sausages’ are sausages heat-treated by scalding, baking, roasting or in any other way, in which minced raw meat has been fully or partially solubilised with common salt and, where appropriate, other technologically necessary salts, usually with the addition of drinking water (or ice), and in which the muscle protein has coagulated more or less coherently during the heat treatment so that the products remain firm when reheated. The quantity of drinking water used varies according to the type of sausage. Up to 10% of blood plasma or serum is sometimes added instead of drinking water for meat and fat; the replacement of drinking water by 5% milk is limited to unsmoked sausages intended for frying, the sausage meat being finely minced.

Basic materials are:

Scalded sausages are the most widely consumed meat products in Europe. They are made by first partially or totally breaking down raw meat with the addition of water or ice and then coagulating all or part of the muscle protein by heat treatment (scalding, roasting, baking or other). This creates a firm structure which makes the sausage firm to cut.

They consist of finely chopped large and small-calibre sausages and cooked sausages with coarse inlay.

These variations can be found in the slicing area and in the sausage segment.

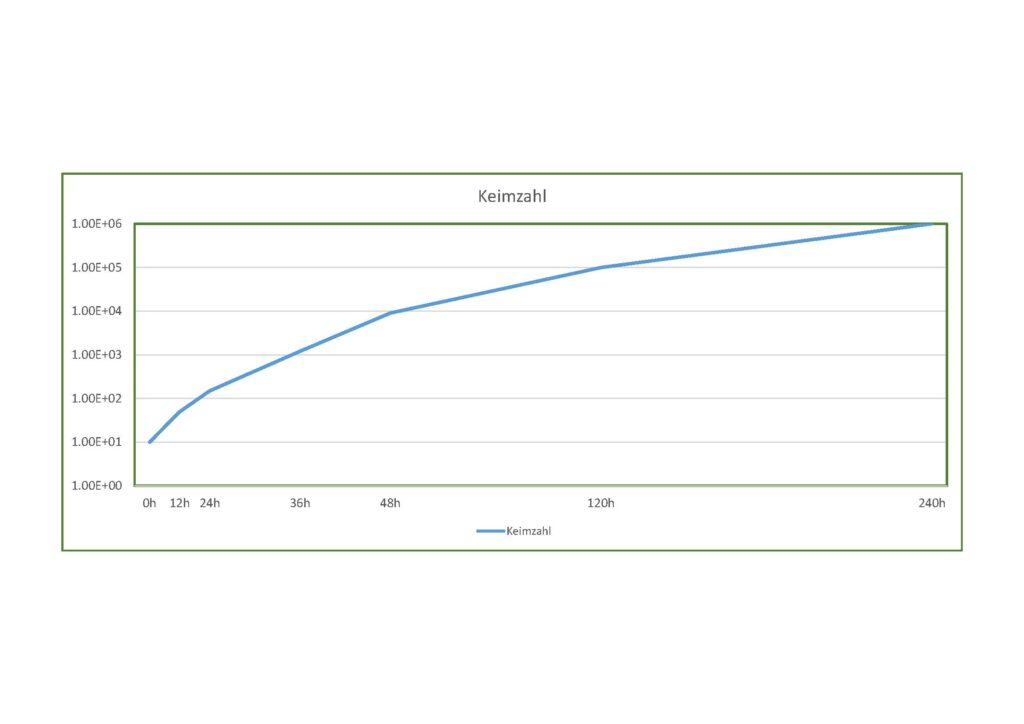

Bacteria and germs are omnipresent in our environment – they are part of our lives. Moreover – without certain micro-organisms we would almost not be able to live, as they fulfil important functions in the human body. However, some species of such genera are also responsible for the spoilage of food.

Meat in the living organism of a healthy animal is practically germ-free. It is not until slaughter that the first germs are introduced into the meat via mechanical action on the carcass.

In order to keep this factor to a minimum:

in the production and processing of fresh meat is a top priority.

is an important criterion for guaranteeing freshness for longer.

Cutter aids are used in the food industry and in butchers’ shops for cutting meat in order to influence the characteristics of the resulting meat. Feed additives are salts which activate the meat protein so that it can form an emulsion. Feed additives may contain additives such as reddening aids, emulsifiers, colouring agents and/or hydrocolloids to support the process.

Phosphate feed additives, pure technology – without taste, because you determine this individually.

The FARBFEST® reddening power is included.

The MEISTERMIX® brand also includes cutter aids with integrated seasoning (compounds). This you will find in the category of boiled sausage spices and seasonings.

phosphate feed additives, so that it goes from liquid the hand. Here the active ingredient is already dissolved and can have a direct effect.

WURSTQUICK® is available for phosphate or citrate base. Traditional with reddening

or as Brat WURSTQUICK® without reddening.

in this series “declaration-free” is written in capital letters, because other forces are at work here. Patented from MOGUNTIA completely without phosphate. In the B-combi-Spice compounds combine the power of

BINDUS®

with the perfect seasoning.

Phosphate cutter aids, perfect without reddening.

Here the pure phosphate is effective and whoever wants to use it as

PE product with emulsifier. Is it available on phosphate or Citrate base.

We will gladly advise you.

For a classic boiled sausage, with the exception of the “white goods”, the consumer expects a red cured colour. Traditionally, this is formed by the curing process with the decomposition product nitrogen oxide from the nitrite curing salt. The antioxidant ascorbic acid and its derivatives are used to accelerate the curing process.

These products are called reddening aids. At MOGUNTIA we know two classes of reddening aids.

products are based on ascorbic acid and accelerate the breakdown of nitrate. In some cases they are also combined with citric acid and other auxiliaries to further improve their effectiveness.

Products, on the other hand, contain the salt of ascorbic acid and have a moderate rate of nitrite degradation. This is particularly important when pre-curing meat to prevent the nitrogen oxide from deflagrating.

For the additional colour of reddened sausages. This gives the sausage the attractiveness and colour stability it deserves. The sausage retains its beautiful red colour even when exposed to strong light.

Emulsifiers such as mono- and diglycerides are used in liver sausage and boiled sausage to support the emulsion and act in combination with the protein contained or in combination with cutter aids. In contrast, protein and fibre preparations based on vegetable substances (SAFTEX® group) can also emulsify without meat protein. These are used to produce pre-emulsions.

This compound series is the cooked sausage class with the extra functionality, for the additional yield you need for your calculation. Flavour enhancer for even more enjoyment.

Taste refiners are the Feng Shui of meat processing. They create the harmony of taste without appearing dominant themselves.

Taste refiner:

MOGUNTIA MIDDLE EAST

Our presence in loco garantuees you a constant and professional service from our experts. We will gladly advise you about the wide range of our products!